タグ一覧:

- サンプル

- sample

- 実績

- decrease

- ポンプ

- increase

- 吐出

- function

- sales record

- 作動力

- japan

- スプリング

- 日本シェア

- 荷重

- シェア

- エアゾール

- share

- シリンダー

- customer

- ガスケット

- delivery time

- gasket

- 納期

- ラバー

- バルブ

- rubber

- product

- how long

ポンプについて

High Viscosity Dispenser の略で、容器を含めた高粘度ポンプシステムを言います。弊社では、これをエアレスポンプと呼んで、底が上ってくる容器を使用して真空を利用したポンプシステムを完成させました。弊社が確認した範囲では、おおよそ粘性率は20,000cP(g/(cm・s)センチポイズ)までのかなりの高粘度まで使用可能と確認しております。原液の比重や他の要素によっても変わってきますので、ご計画商品の使用用途と原液をお送りください。弊社にてスペックを確認致しますので、お客様でのサンプル確認が可能です。

HVD stands for high viscosity dispenser, a pump system including the bottle for high viscosity contents. We call it “airless pump”, a pump system using a vacuum produced by lifting the bottom of the bottle. As far as we know, this pump can be used on contents with extremely high viscosity, up to about 20,000 cP(g/(cm.s)). However, it does depend on the specific gravity and other factors of the contents as well. Please send us a sample of your contents and let us know the purpose of use. We will carry out compatibility tests and inform you of the results.

一般的には原液(内容液)によってポンプを使い分けることは無く、ご使用用途(霧で噴霧したいのか、乳液で出したいのかなど)によって使い分けられます。しかし、ポンプを構成する部品(樹脂等)に適さない成分が含まれている場合が有りますので、PP、PE、 POM、ゴムやスプリングなどを侵す、又は膨潤する原液の場合は、必ずご確認を御願い致します。

Generally speaking, you do not have to change the pump depending on the type of the contents; it depends on the purpose of use (spraying a mist or discharging an emulsion). However, the contents may include a substance which are incompatible with some parts (such as resin) of the pump. Please feel free to consult our sales representatives, We will carry out compatibility tests for your products.

当社では、基本的に原液(内容液)を、実際に、10回連続作動させ、その重量変化平均値を一回の噴射量、吐出量としています。弊社内の作動試験では、水またはアルコールを使って噴射量、吐出量を表わしています。

We put the contents in a bottle and pump the bottle 10 times consecutively to measure the average spraying/discharging amount. This average is the spraying/discharging amount we usually quote. In our internal performance test, we use water to measure this spraying/discharging amount.

ポンプの仕様を決めるのに必要な項目は何ですか?

What are the essential factors to determine the specifications of the pump?

どのような原液(内容液)を、どのように(霧で噴霧したいのか、乳液で出したいのか)、どのくらいの量(一回の吐出量)を出したいのか?が基本項目です。ご計画商品のボトルの有無がネジサイズに関わってきます。もう少し項目を考えると、噴霧パターンなども必要項目として上げられます。ポンプのデザインや色調は消費者の感性に訴える必須項目となります。ご一緒に検討したいと思いますので、要望をお聞かせ下さい。

The basic factors are 1) the characteristics of the contents and 2) how to discharge the contents (spraying as a mist or discharge as an emulsion), and 3) the spraying amount (per pumping). The presence or absence of a bottle on your side affects the size of the screw. Additionally, the spraying patter is also a necessary factor. The design and the color of the pump are important to attract consumers. Please send us a sample and we will check and propose the best product for you.

粘度の高い内容液を吐出後、吐出口を空気に触れないようにフタをするシャットオフ機構、もしくは吐出口に残った内容液をポンプ内に引き込むようなバックサクション機構を持ったポンプをご提案します。

ご計画商品の原液(内容液)をお送りください。弊社技術部で確認して、対処方法をご提案させていただきます。

To prevent clogging, we recommend that you use a cover on the nozzle to avoid contact with air, or a structure that draws the remaining contents into the pump after discharging.

Please send us a sample of your contents. Our technical staff will check the contents and suggest the best idea.

弊社が確認した範囲では、おおよそ粘性率は20,000cP(g/(cm・s)センチポイズ)までのかなりの高い粘度まで使用可能と確認しております。(特定商品)原液の比重や他の要素によっても変わってきますので、ご計画商品の使用用途と原液を、お送りください。弊社にてスペックを確認致します。

実際に容器に原液をいれてお客様自身でもご確認をお願いします。

As far as we know, our products can be used on contents with extremely high viscosity, up to about 20,000 cP(g/(cm.s)poise). However, it does depend on the specific gravity and other factors of the contents as well. Please send us a sample of your contents and let us know the purpose of use. We will carry out compatibility tests and inform you of the results.

It is very important to put the contents in a bottle and carry out the test in a practical manner.

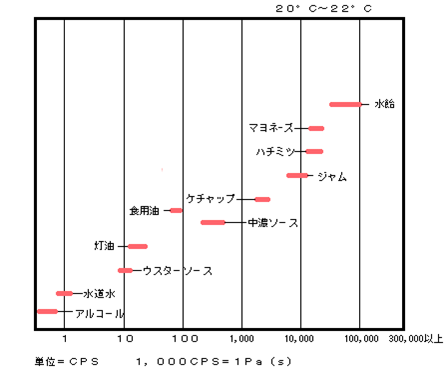

(表)液体粘度の目

お受けいたします。ご計画商品の公開可能な情報、吐出量などをお知らせ下さい。ポンプの作動性などを検証して、ご提案いたします。お客様自身でも原液による必要な確認試験及び評価をお願いします。

We are very happy to carry out the test and choose the pump for you. Please inform whether you would like the contents to be discharged as a mist or an emulsion, and the discharging amount per pumping. We will check the spray load of various pumps and inform you of our proposed pump. We will also send you a sample pump. You can change the pump to best fit your customers. We believe that your product is improved by checking the sample on both ends, you and Mitani.

直圧式とは、一般的に乳液やシャンプーなどに使われ、内容液を静圧のまま吐出させるポンプを指します。ドロップタイプと呼ばれることもあります。用途としては、各種乳液、高粘度の原液を吐出する場合に使用されます。

蓄圧式とは、内容液に圧力を加え、一定の圧がかかると弁が開き噴霧する機構のポンプを言います。内容液に圧力が加わりますので、霧状に噴霧するタイプに適しています。ミストタイプと呼ばれることもあります。用途としては、香水、ヘアスプレー、空間用の霧等を要求される場合に使用されます。

The direct injection system is used for emulsion and shampoo products to discharge the contents with static pressure. It is also called the “drop type”. This system is used to discharge various emulsion and high viscosity contents.

The accumulator injection system gives pressure to the contents and a valve is opened for discharging when the pressure reaches a certain level. Since the pressure is applied to the contents, it is appropriate for a mist-type product. Therefore, it is also called the “mist type”. This system is used for air sprays such as perfume and hair sprays.

基本的には、霧ポンプと乳液ポンプの吐出原理と内部構造は同じです。目的別に吐出機構を分けています。霧用は、霧にするために、圧力を高めて出す機構を採用して、噴霧後は液切れがし易い構造としています。乳液用は粘度の高い原液を吐出するように、広い通路を設けて作動のスピードでそのまま押し出す機構にしています。

The mist pump and the emulsion pump basically have the same discharging mechanism and inner structure. The nozzle section is different. In a mist pump, the pipe of the pump is narrow to allow the increase of pressure and to avoid dripping after spraying. If your product is meant to spray a fine mist, we provide an accumulator injection pump. In an emulsion pump, the pipe of the valve is wider to discharge high viscosity contents smoothly which allows the contents to be pushed at a constant rate from the initial push.

弊社ポンプは、機構コア部にラバーシステムを導入し業界で最も軽い作動力を誇っています。

弊社は、お客様のご計画商品が、消費者の感性に合った商品にするために、ご一緒に誠意を込めて検討する用意がありますので、弊社営業にご相談ください。

Two interpretations are possible when you say “works softly with light finger load”; one is that the pushing load of the pump is light; and the other is that pump action is soft and smooth.

If you would like to lighten the pushing load, it requires low inner pressure and proper adjustment of the spring. In addition to the spring load, the following factors affect the pushing load; viscosity of the contents, sliding resistance of the piston valve, the internal diameter of the cylinder, and flow resistance of the nozzle (nozzle caliber). The spring load is determined depending on the viscosity of the contents. Please let us know what level of pushing load you prefer. We provide various products with different internal diameters of cylinders, different diameters of nozzle caliber, and different springs.

When soft and smooth action is required, uneven surface and unbalanced pushing load must be avoided. When the contents include alcohol, the sliding resistance of the piston valve may increase.

We are ready to discuss with you in a frank manner and propose an idea in order to make a product which is fully in touch with your customers’ sensibilities. Please consult our sales representatives.

弊社では多種類のノズルをご用意しています。用途に応じたノズルをご提供できますのでお気軽にご相談下さい。

As the pump works under the same mechanism as a syringe, finer mist can be produced by increasing the inner pressure or changing the nozzle type. Depending on the viscosity of the contents, there are limitations to the inner pressure.

Additionally, when increasing the pressure in the tank within the pump, the spray load increases (in this case, consumers usually feel heavy action) and the tank wall has to be thicker. This is why there are limitations to the increase of the inner pressure.

Generally, finer mist is made by changing the nozzle type without increasing the inner pressure too much. We have various nozzles and you can evaluate our nozzles by yourself whether they make mist fine enough for you. Please let us know the details of your planned product and required spray particle size. We will suggest a solution.

ポンプ作動を行うと、内容液の圧力が高められます。ノズル内部の機構に溝が切ってあり、この経路の溝がスクリューの役目をします。圧力のかかった内容液はスクリューによって回転しながら、噴射口を通るようにします。この時に発生する回転の勢いで霧になります。庭の草木に霧の散水を行うノズルと同じ原理です。

In pumping, the pressure of the contents increases. There is a spiral groove in the inner mechanism of the nozzle that works as a screw. The pressurized content is rotated by this screw and when the content passes through the jet nozzle, this pressure makes the content misty. This mechanism is the same as that of a water sprinkler in a garden.

注射器の原理と同じ要領で、ボトル内にある内容液を、パイプを通してタンクに吸い上げ、タンクに溜まった内容液を再度押し出し、吐出(噴霧)しています。

The mechanism of the pump to discharge the contents is the same as that of a syringe. The contents in a bottle is collected through the pipe and sent to a tank. The contents in the tank is pushed again to be discharged (or sprayed).